Marble, a timeless classic, has never faded from the world of design and architecture. The combination of black and white marble, with its clean lines, has long created spaces that are comfortable, natural, and sophisticated. Yet, a new trend is quietly emerging—Colored Marble Stone—infusing spaces with unprecedented vibrancy and emotional depth through its bright, saturated tones. This leads us to wonder: is it reshaping our traditional color aesthetics?

From eternal tranquility to contemporary boldness, colored marble does not replace the classic but expands the expressive boundaries of stone. It liberates spaces from the dialogue of neutral tones, granting them a richer emotional language.

Colored Marble Application Cases: Integrating Natural Beauty into Life

1. A Staircase of Hues: In a collaborative work by architect Alan Shulman and designer Frank de Biasi, a marble staircase becomes the focal point. Its treads are clad in panels of various brightly colored stones, including vibrant Colored Marble Stone, resembling a solidified rainbow that connects not only different spaces but also tradition and innovation.

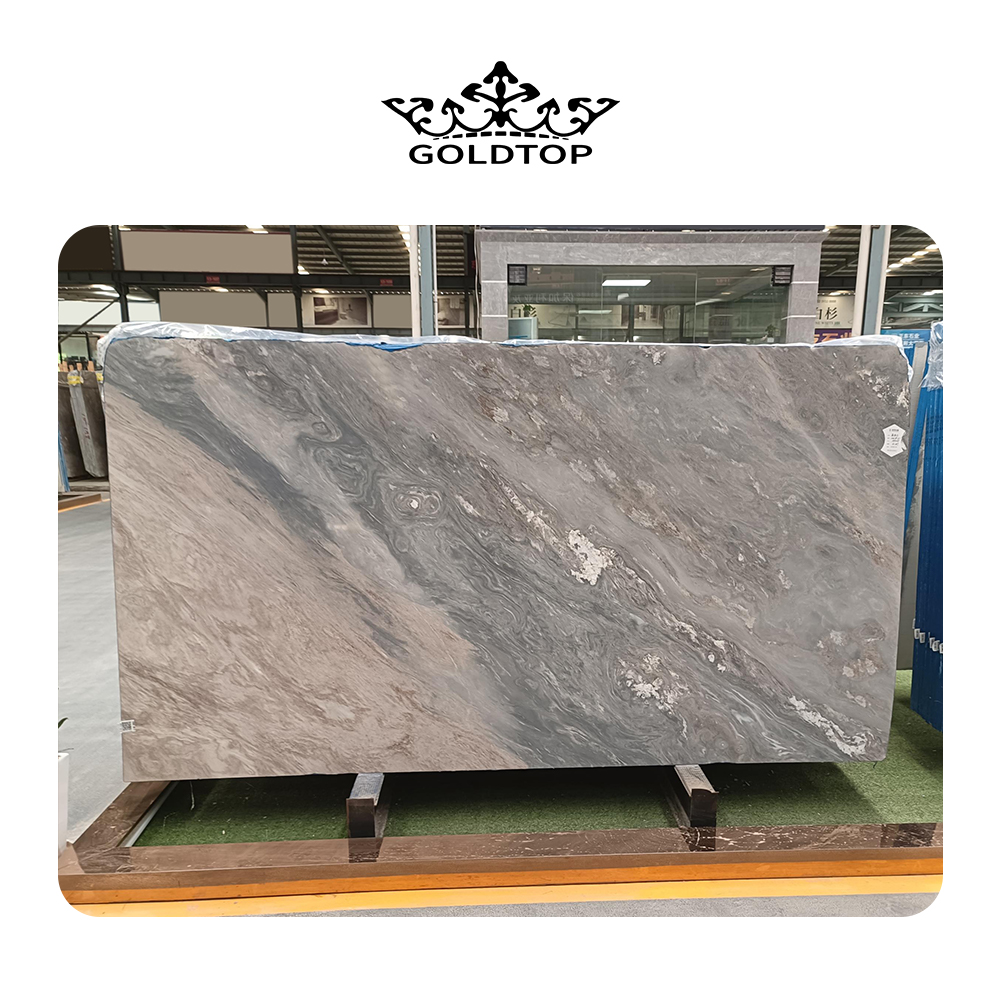

2. An Artistic Focus in the Kitchen: In a New York apartment, designers from LeWhit eschewed a conventional backsplash in favor of gray breccia Capraia marble with burgundy speckles. This distinctive Colored Marble Stone wall instantly elevates the kitchen into a large-scale art piece, showcasing the dramatic appeal of natural stone veining.

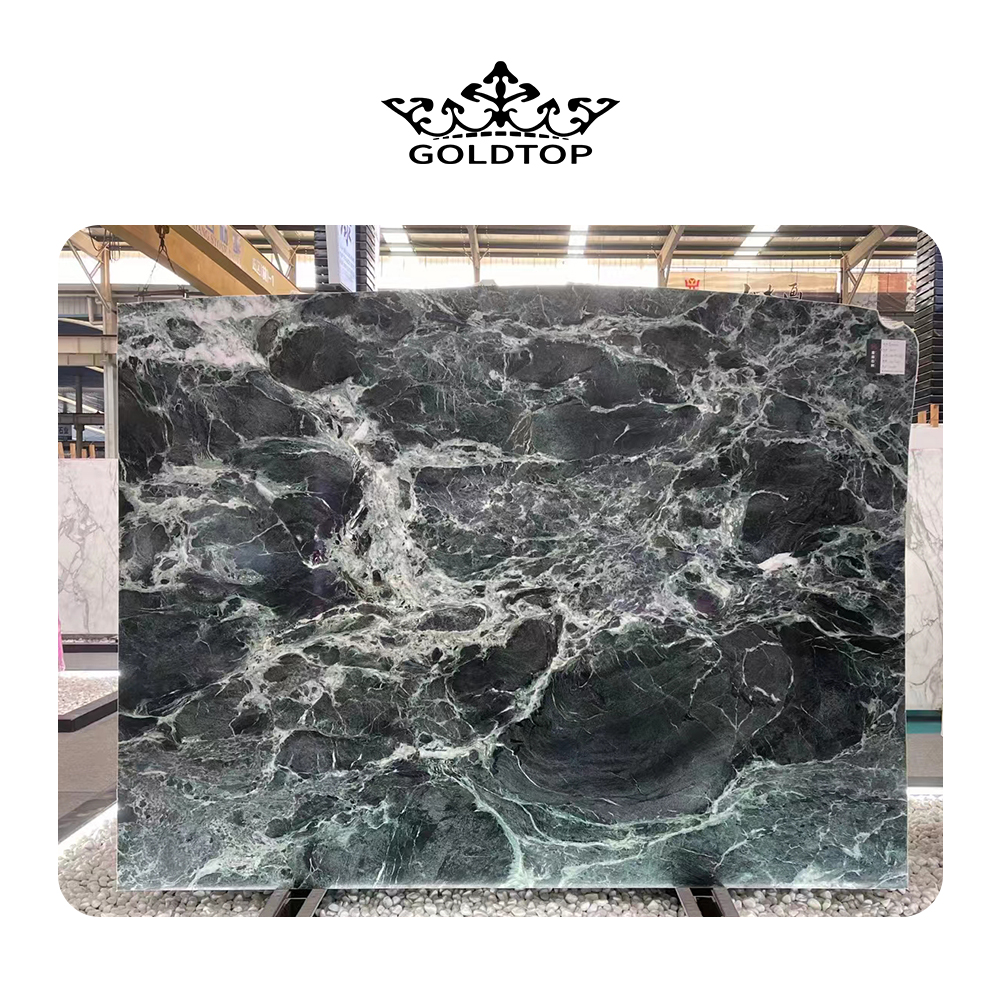

3. A Colorful Manifesto in Milan: At Milan Design Week, the collaborative project between SolidNature and OMA design studio served as a grand celebration of colored marble's beauty. Particularly noteworthy was a series of marble furniture pieces designed by architects Ellen van Loon and Giulio Margheri. Even more stunning was an installation featuring nine different types of Colored ONYX Marble, their gentle glow resembling a gateway to a natural wonderland or another dimension, highlighting the stone's innate spirituality.

4.A Gravity-Defying Cabinet: A cleverly designed marble cabinet perfectly illustrates the balance between function and art. Constructed primarily from green marble with Colored Marble Stone shelves, this Marble Wall Cabinet rests on a rotating pivot. Its substantial upper mass appears to "float" precariously yet precisely on a minimal base, challenging visual perception while remaining fully functional. Designer Sabine Marcelis explored the "delicate balance between aesthetics, material, form language, and function" through this piece.

Behind the Trend: A Deep Longing for Nature and Permanence

Since the pandemic, there has been a profound yearning to reconnect with nature. This trend manifests in design as a shift: designers no longer merely adjust natural materials to fit a chosen concept or style. Instead, they use these materials as the core inspiration, building entire spatial narratives around them. Colored marble is the perfect vessel for this philosophy.

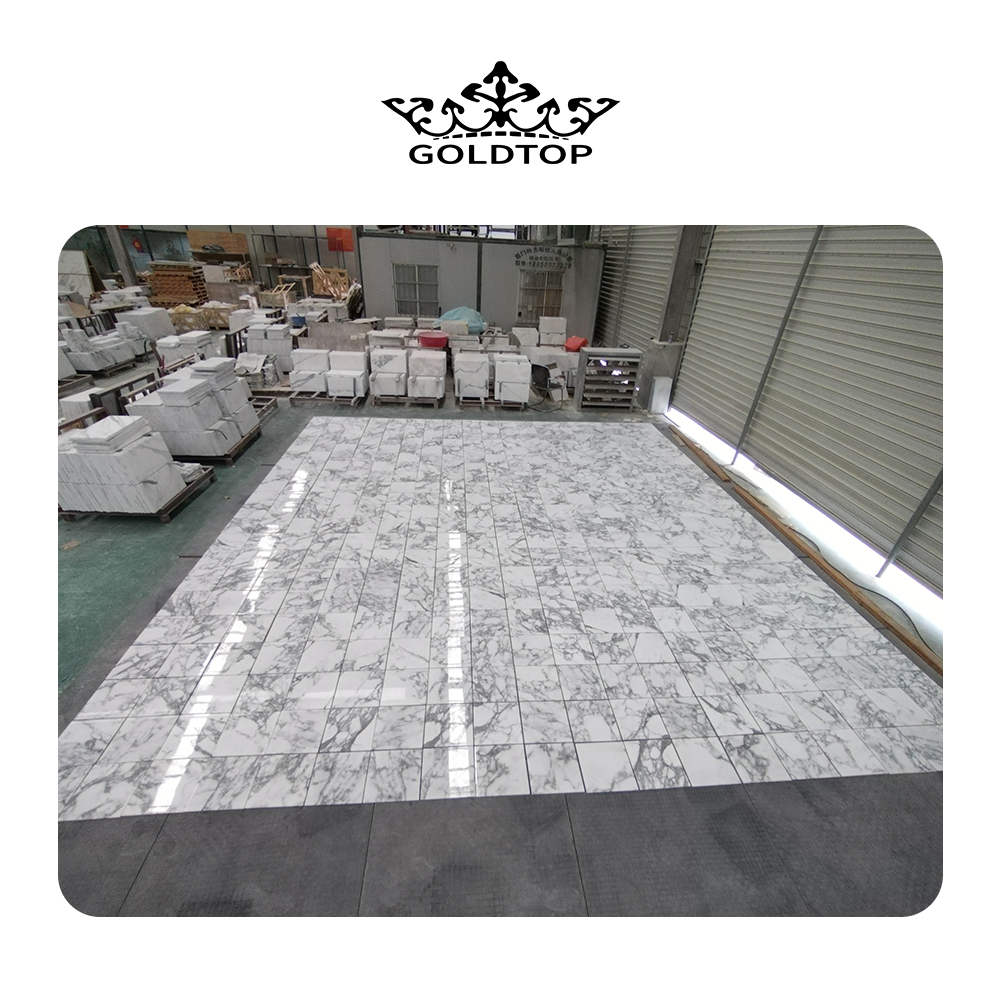

Designers and their clients cherish marble not only for its visual beauty but for the sense of permanence it carries—a connection to the deep history of the earth itself. It transcends fleeting trends, embodying true, lasting durability. Whether laying down a stunning Colored Marble Floor or crafting a unique feature wall with Colored Jade Marble, it reminds us that the most moving designs often stem from the unadulterated splendor and power of nature itself.

The rise of colored marble is not a disruption, but a renewal. It invites us to rediscover the infinite possibilities of natural materials with a more open and perceptive eye, allowing the classic to stride into the next eternity, blossoming with color.

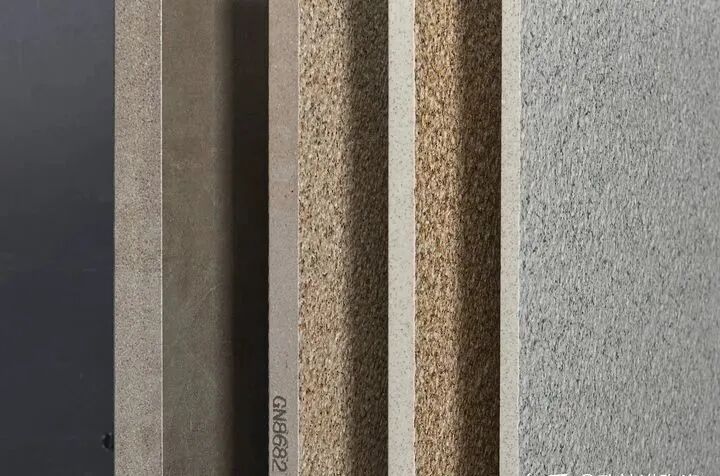

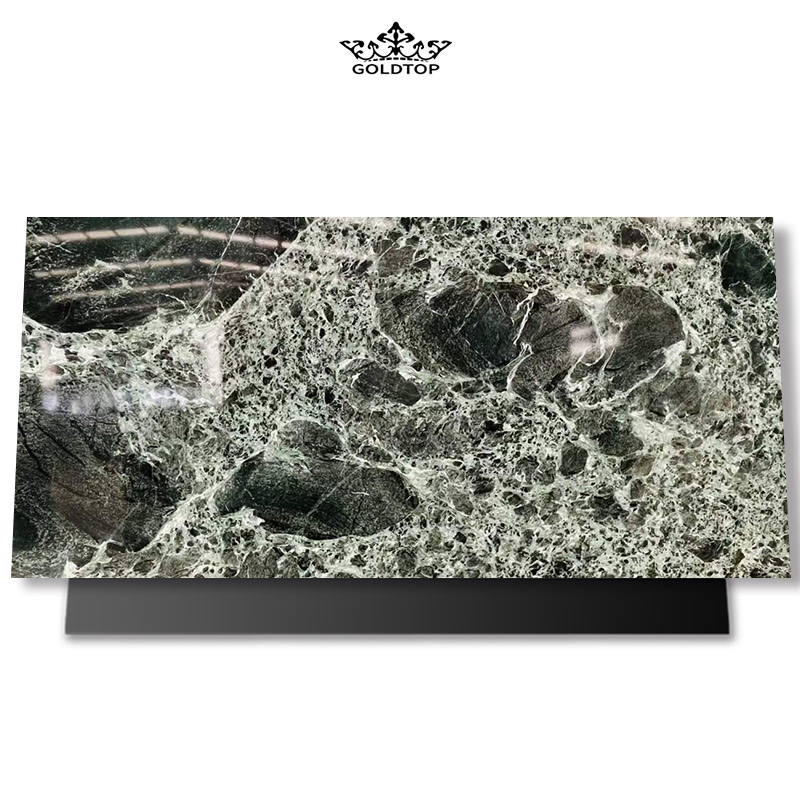

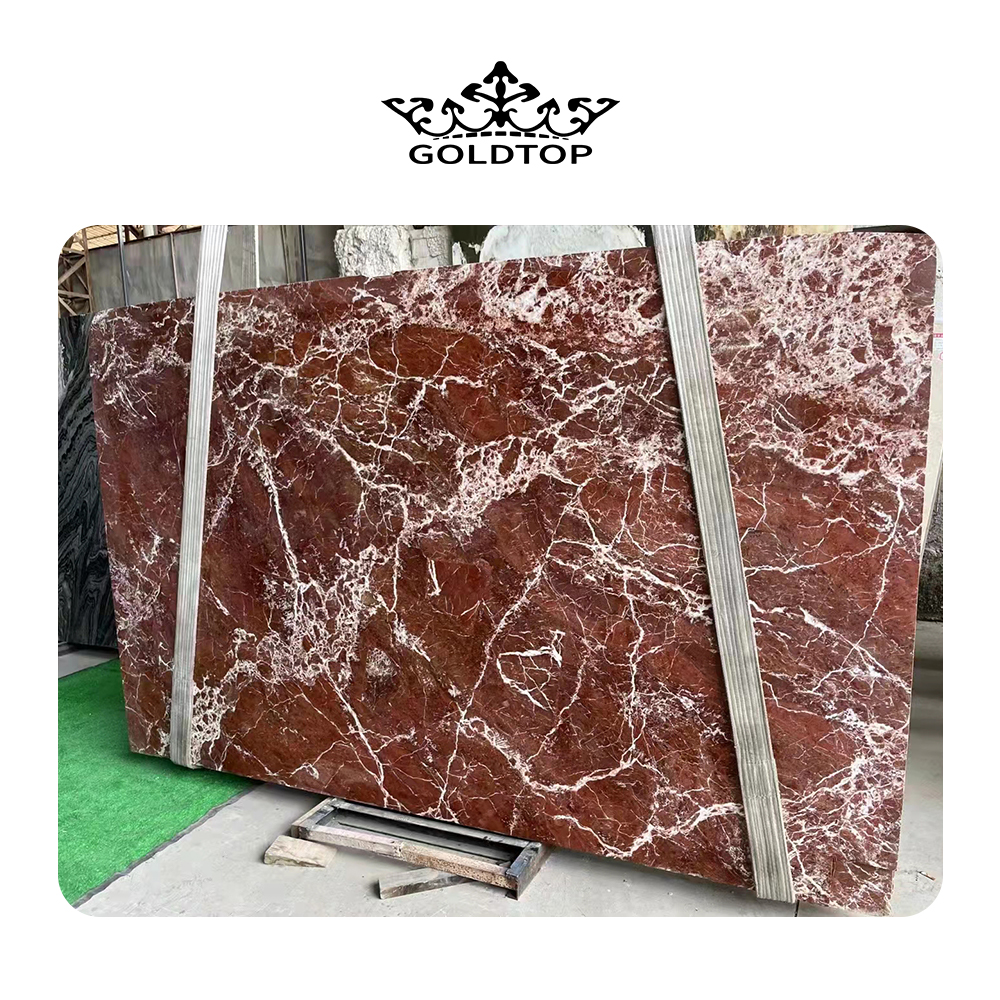

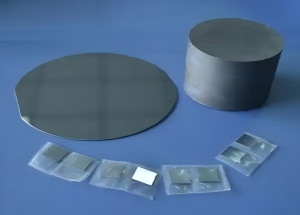

Finally, let me recommend some of the stone materials :

|

|

|

| Verde Ming Green Marble | Pink onyx | Arabescato Orobico Rosso Red Light Marble |

|

|

|

| ROSA NORVEGIA Marble | Cold Emerald Marble | Cloudy Wave Marble |